Introduction to PCB Manufacturing Machines : Types

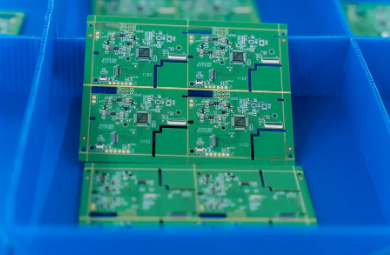

In the ever-evolving world of electronics, Printed Circuit Boards (PCBs) are the unsung heroes that form the backbone of most electronic devices. From smartphones to industrial machinery, PCBs provide the essential connections between various components, ensuring that signals are transmitted effectively and reliably. As demand for electronic devices continues to surge, the need for efficient, high-quality PCB manufacturing has never been greater. This is where PCB manufacturing machines come into play.

These machines are pivotal in the production process, transforming raw materials into complex circuit boards that meet stringent specifications. In this introduction, we will explore the different types of PCB manufacturing machines and highlight some of the key players in the industry.

Types of PCB Manufacturing Machines

1. PCB Fabrication MachinesPCB fabrication is the process of creating the physical circuit board from a design. This involves several key steps, each facilitated by specific types of machines:

– Photoplotters: These are used to create photomasks for PCB production. A photomask is a plate with patterns that will be transferred onto the PCB’s surface. Photoplotters use high-precision imaging technology to ensure accurate pattern reproduction.

– Drilling Machines: Once the PCB pattern is applied, drilling machines create holes for components and vias. These machines are equipped with high-speed spindles and precision control systems to ensure that holes are drilled accurately and efficiently.

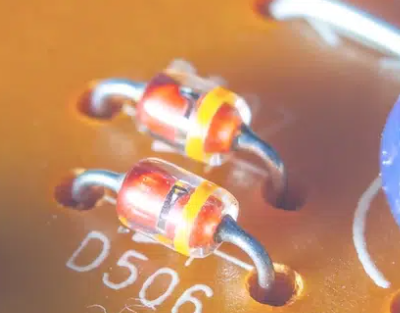

– Etching Machines: After drilling, the PCB is subjected to an etching process to remove unwanted copper and leave behind the circuit pattern. Etching machines use chemical solutions or abrasive materials to strip away excess copper while preserving the desired circuitry.

– Laminators: Laminating machines are used to bond multiple layers of PCBs together. This process involves applying heat and pressure to laminate the layers into a single, multi-layer board. Laminators ensure that the layers are aligned correctly and that the adhesive bonds are strong.

– Solder Mask and Silkscreen Printers: Solder masks are applied to prevent solder from bridging between circuit paths, while silkscreen printers add labels and markings to the PCB. These machines use advanced printing technologies to apply precise coatings and markings.

2. PCB Assembly MachinesOnce the PCB is fabricated, it needs to be assembled with electronic components. This step involves several specialized machines:

– Pick and Place Machines: These are crucial for the assembly process. Pick and place machines automatically position and place components onto the PCB. They use high-speed cameras and advanced algorithms to ensure components are placed accurately and efficiently.

– Soldering Machines: There are various types of soldering machines used in PCB assembly. Wave soldering machines apply solder to the entire PCB at once, while reflow soldering machines use heat to melt solder paste and create precise solder joints. Selective soldering machines target specific areas for soldering, reducing the risk of damage to sensitive components.

– Inspection Machines: Quality control is essential in PCB manufacturing. Automated Optical Inspection (AOI) machines use cameras and image processing to detect defects such as soldering errors, missing components, or alignment issues. X-ray inspection machines can inspect internal layers and connections that are not visible externally.

3. PCB Testing MachinesTesting is a crucial step to ensure the functionality and reliability of the PCBs. Testing machines include:

– In-Circuit Testers (ICT): These machines test the electrical connections and functionality of the PCB by probing each point and checking for continuity, shorts, and other electrical faults.

– Functional Testers: Functional testers simulate the PCB’s operating environment to ensure that it performs as expected. These testers are used to evaluate the board’s overall functionality and identify any operational issues.

在线留言询价

What is “component placement” in PCB?

15 Common PCB Circuit Effects

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| RB751G-40T2R | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| STM32F429IGT6 | STMicroelectronics | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: