- Ameya360 Component Supply Platform >

- Trade news >

- BIWIN Solutions for Communication Modules: High-Speed, Stable, and Built for Seamless Data Flow

BIWIN Solutions for Communication Modules: High-Speed, Stable, and Built for Seamless Data Flow

The Internet of Things (IoT) is on a steep upward trajectory. Statista predicts that by 2025, the world will see a surge of connected IoT devices to 29.422 billion units from 9.757 billion units, with CAGR reaching 11.67%. This explosion isn’t just powering the deployment of more smart gadgets; it’s opening up huge opportunities for hardware and storage tech. At the core of this ecosystem, communication modules serve as the vital link between the physical and digital realms. Their performance directly shapes the efficiency, stability, and security of IoT systems, handling everything from collecting sensor data to transmitting it wirelessly to the cloud or end devices—powering critical functions like remote monitoring and data analysis.

With the rapid expansion of IoT applications, storage components within communication modules face heightened challenges. They must excel in high-bandwidth data transmission, multitasking concurrency, continuous data streaming over extended periods, efficient and stable data read/write operations, data security protection, and system compatibility to ensure real-time transmission and secure storage of critical data.

In response to these industry challenges head-on, BIWIN draws on its “integrated R&D and packaging” expertise, along with its expertise from markets such as smartphones and smart wearables, to offer a comprehensive storage solution product matrix for communication modules, including eMMC, LPDDR, eMCP, uMCP, and more. These products have been widely applied to power 5G/4G and smart modules from industry leaders like Quectel, Fibocom, and MeiG Smart, providing solid foundations for the efficient and reliable operations of communication networks.

01 Tackling Tough Scenarios with Top-Notch Storage

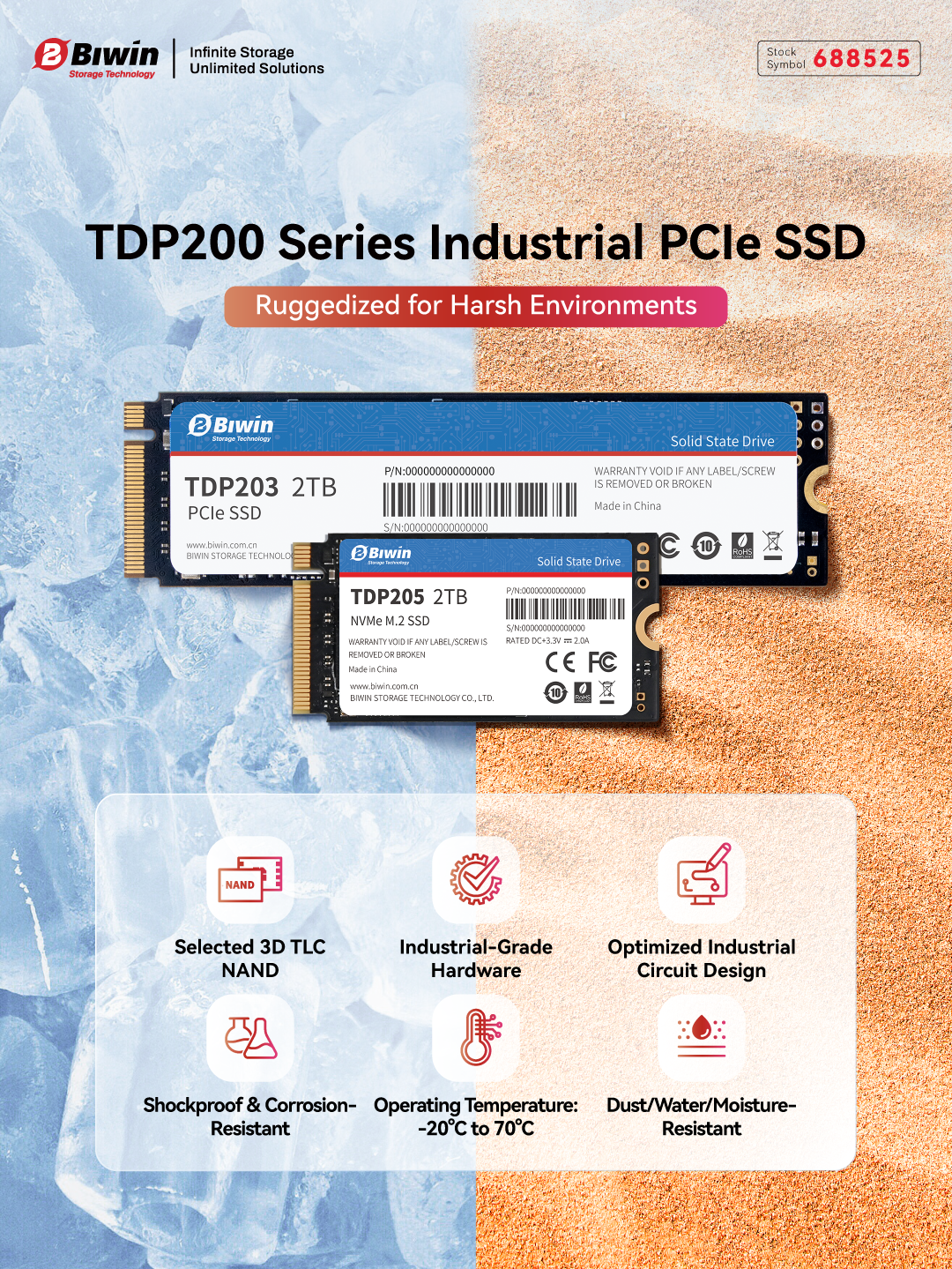

In practical deployments across fields such as smart metering, industrial applications, routers, automotive systems, and POS machines, communication modules face numerous challenges. Particularly in outdoor environments, harsh weather, extreme temperatures, humidity fluctuations, prolonged continuous operation, and electromagnetic interference can all impact module performance. Any data loss or delay could result in IoT system failures or degraded service quality.

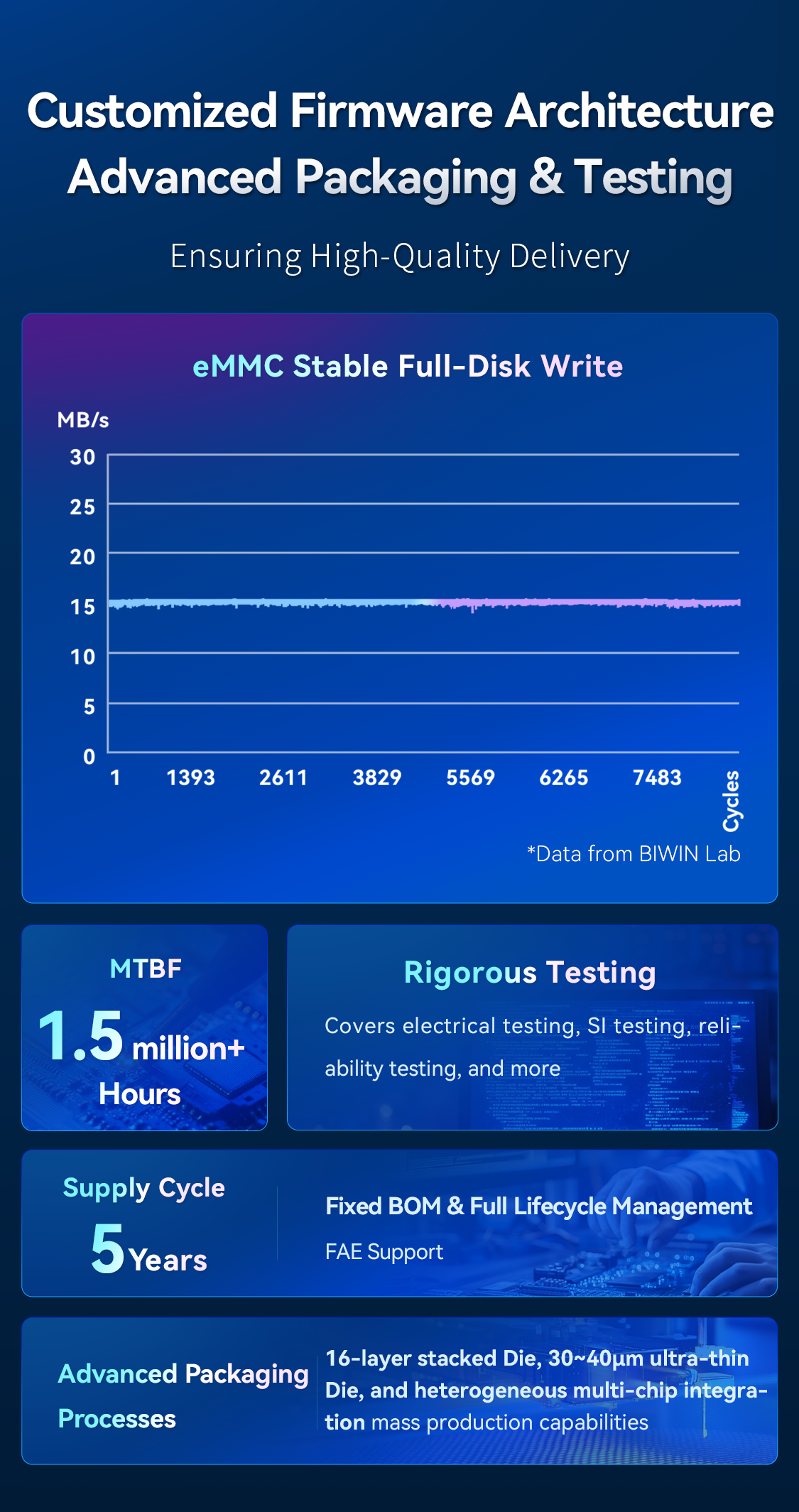

Taking specific IoT application scenarios as an example, in surveillance systems requiring uninterrupted high-definition video recording, storage components must maintain stable, high-speed read/write performance. To meet these demanding requirements, BIWIN’s storage chips are featured with custom-designed firmware architectures, dynamic SLC caching and unique direct-write solutions, and firmware optimizations for garbage collection and data encryption, contributing to the consistently stable data read/write operations. Testings show that BIWIN’s eMMC products achieve full-disk write speeds exceeding 15MB/s with performance fluctuations below 5%, perfectly aligning with IoT-specific application standards. Additionally, BIWIN’s storage chips support remote firmware upgrades for communication modules, enhancing device operational efficiency.

On the reliability front, BIWIN’s chips are loaded with cutting-edge packaging technologies like multi-layer die stacking, ultra-thin dies, and heterogeneous multi-chip integration, capable of realizing a perfect balance among performance, durability, and heat management. Meanwhile, the chips have also been tested with rigorous processes, covering electrical testing, signal integrity (SI) testing, reliability testing, and application testing. These chips can withstand gravitational acceleration up to 1500G, vibration amplitudes of 20-2000Hz, and achieve a mean time between failures (MTBF) exceeding 1.5 million hours, ensuring high-quality delivery and consistency across all aspects.

02 Building a Comprehensive Product Matrix to Provide Efficient and Reliable Storage Support

With key attributes such as highly stable read/write performance, exceptional reliability and durability, and excellent compatibility, BIWIN’s eMMC, LPDDR4X, eMCP3/4x, and uMCP2.2 series products have earned certifications from mainstream SoC platforms like Qualcomm, MediaTek, and Unisoc. They have been integrated into the supply chains of multiple renowned communication module manufacturers, continuously empowering the stable operation of communication modules.

In conclusion

As technologies such as AI, edge computing, 5G/6G, and LPWAN become deeply integrated, the IoT will evolve into more mature and diverse forms, permeating all aspects of life and generating immense demand for data computation, processing, transmission, and storage. Facing this trend, BIWIN will capitalize on its comprehensive strengths in R&D, controller design, packaging and testing, and supply chain management to deepen collaboration with communication module vendors and platform providers, fully addressing the multidimensional customization needs of edge-side communication modules for storage performance, reliability, and stability and jointly accelerating the expansion of IoT application boundaries.

Online messageinquiry

BIWIN Built-in BGA SSD Plus Mini SSD Make Robots Smarter, Easier to Use, and Longer-Lasting

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi |

| model | brand | To snap up |

|---|---|---|

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: