Murata:Radisol Redefines Antenna Interference Countermeasures for Smartphones and Wearables

Murata Manufacturing Co. Ltd announces the launch of Radisol – an innovative product designed to suppress interference between nearby antennas with low insertion loss, improving isolation and antenna radiation efficiency. This world-first solution is specifically engineered to meet the demands of compact modern devices like smartphones and wearables, offering benefits such as reduced power consumption, miniaturized construction, and enhanced communication quality. In addition, Radisol has been adopted by Motorola Mobility LLC (Headquarters: Libertyville, Illinois, USA, President: Sergio Buniac), in the new Edge series of smartphones scheduled to be released in August 2024. Motorola has realized a method of improving the characteristics of Wi-Fi® antennas by using Radisol.

As the demand for smaller smartphones and wearable devices grows, the number of antennas is also increasing to accommodate the expanding range of communication methods and bands. Additionally, MIMO technology to improve communication quality and speed is encouraging an increase in the number of antennas, while new designs such as foldable smartphones are encouraging antenna crowding. This has posed new difficulties, specifically the implications on antenna isolation and the decline in antenna effectiveness, as the interference of nearby antennas leads to a decrease in radiation efficiency.

Although discrete filters are a common solution for improving antenna isolation, they are not suitable when communication bands are closely situated, as insertion loss can impair antenna performance and occupy valuable board space. To address these challenges, Murata has created Radisol, a low-loss filter for antenna area that uses Murata’s unique ceramic multilayer technology and RF circuit design technology.

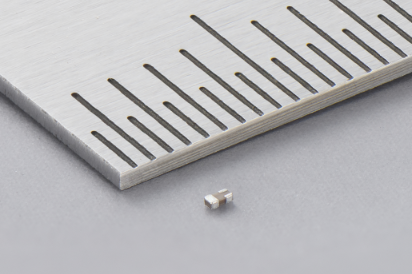

Antenna engineers usually construct a filter circuit using discrete L and C chip components to implement effective countermeasures. Instead, Radisol is just a single 0603-sized component that resolves the persisting challenges of antenna performance and packaging constraints. It effectively suppresses antenna interference, without significantly impacting the passband, and results in enhanced radiation efficiency and reduced power consumption.

Each Radisol component operates as a dedicated filter circuit designed specifically to mitigate the antenna interference associated with a specific communication band. The compact component integrates one capacitor and two inductors, providing band-stop filter characteristics within a single chip. Radisol features a unique design that utilizes the generation of lossless mutual inductance by two magnetically coupled coils. This setup forms a band-stop circuit with no notable insertion loss in the communication band. This specialized approach to antenna isolation enables Radisol to offer enhanced performance, with low insertion loss and high efficiency and system integration.

Included in the Radisol family are variants designed to effectively address the needs of common bands, including 2G & 5G Wi-Fi® as well as GPS signals. This eliminates the necessity of designing discrete filter circuits, simplifying the implementation of countermeasures. Murata will continue to expand upon the initial product lineup to further meet market demands and drive further innovation in antenna technology.

“By using Radisol engineers can address the challenges of modern communication devices without compromising signal integrity and radiation efficiency,” said Satoru Muto, General Manager of New Business Incubation Department at Murata. “By utilizing Murata's cutting-edge technology, this solution takes integration to a whole new level, eliminating the need for complex discrete filter circuits and saving valuable space.”

Radisol samples are available for evaluation and mass production has already begun in June 2024. To learn more about Radisol or to request samples, please contact your local Murata representative or visit here.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| CDZVT2R20B | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: