- Ameya360 Component Supply Platform >

- Trade news >

- ROHM Offers LogiCoA™: the Industry's First* Analog-Digital Fusion Control Power Supply Solution

ROHM Offers LogiCoA™: the Industry's First* Analog-Digital Fusion Control Power Supply Solution

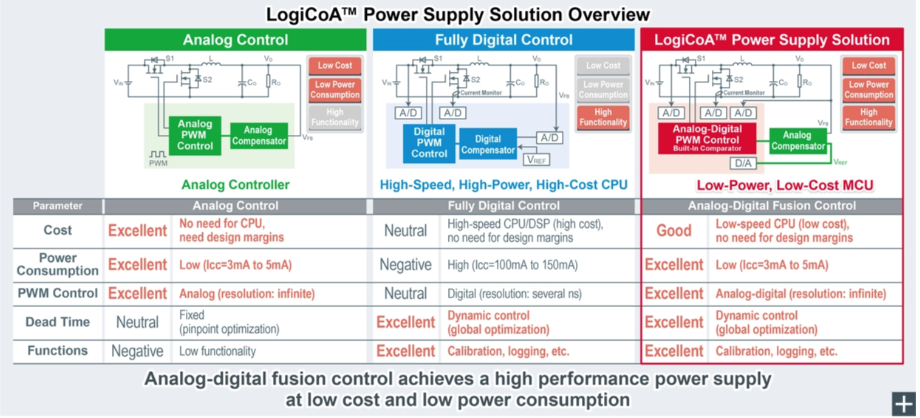

ROHM has established LogiCoA™, a power supply solution for small to medium power industrial and consumer equipment (30W to 1kW class). It provides the same functionality as fully digital control power supplies at low power consumption and cost equivalent to analog power types.

Analog controlled power supplies are commonly used in industrial robotics and semiconductor manufacturing equipment that operate in the medium power range. However, in recent years these power supplies are also required to provide a high level of reliability and precise control that make it difficult to meet market demands with analog-only configurations. On the other hand, while fully digitally controlled power supplies enable fine control and settings, they are not widely adopted in the small to medium power range due to the high power consumption and cost of the digital controller. To address this issue, ROHM developed the LogiCoA™ power solution that leverages the strengths of both analog and digital technologies. High performance low power LogiCoA™ MCUs are utilized to facilitate control of a variety of power supply topologies.

The LogiCoA™ brand embodies a design philosophy of fusing digital elements to maximize the performance of analog circuits. ROHM’s LogiCoA™ power solution is the industry’s first* “analog-digital fusion control” power supply that combines a digital control block centered around the LogiCoA™ MCU with analog circuitry comprised of silicon MOSFETs and other power devices.

In a fully digital control power supply, the functions handled by digital controllers such as high-speed CPUs or DSPs can be processed by low-bit MCUs, making it possible to achieve increased functionality that is difficult to realize with an analog control power supply at low power consumption and cost. This solution allows for the correction of performance variations in peripheral components according to the power supply circuit by storing various settings such as current and voltage values in the LogiCoA™ MCU. As a result, there is no need to consider design margins unlike with analog control power supplies, contributing to smaller power supplies that provide greater reliability. On top, as operation log data can be recorded in the MCU's nonvolatile memory, it is ideal for power supplies in industrial equipment that require logging as a backup in case of malfunction.

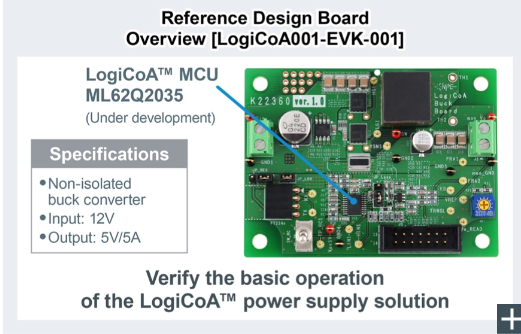

The evaluation reference design REF66009 allows users to experience the LogiCoA™ power supply solution in a non-isolated buck converter circuit. Various tools necessary for evaluation are also offered, including circuit diagrams, PCB layouts, parts lists, sample software, and support documents, while actual device evaluation is possible using the optional LogiCoA001-EVK-001 evaluation board.

Going forward, ROHM will continue to develop LogiCoA™ MCUs to support various power supply topologies, contributing to achieving a sustainable society by making the power supply block (which accounts for the majority of power loss in applications) more energy efficient and compact.

LogiCoA™ BrandLogiCoA™ is a brand that embodies a design philosophy of fusing digital elements to maximize the performance of analog circuits. By combining the advantages of analog circuitry with those of digital control, it is possible to maximize the potential of circuit topologies, contributing to more efficient power utilization. As LogiCoA™ is a design concept that can be applied not only to the power supply field, but also to power solutions as a whole, ROHM is considering its application in future products and solutions.

Details of the LogiCoA™ Power Supply Reference DesignThe REF66009 evaluation reference design offered on ROHM's website allows users to verify the functionality of the LogiCoA™ MCU along with the basic operation of the LogiCoA™ power supply solution using a non-isolated 12V buck converter circuit. Sample software available on the reference design page makes it possible to confirm the sequence control of execution tasks and the monitoring of various parameters in the actual set using the LogiCoA001-EVK-001 reference board. For more information on the reference board, please contact a sales representative or the contact page on ROHM’s website.

Application Examples• Industrial robots

• Semiconductor manufacturing equipment

• Gaming applications

Supports mounting in a wide range of general industrial equipment and consumer devices (30W to 1kW).

About the LogiCoA™ MCUROHM is developing LogiCoA™ MCUs optimized for integrated analog-digital control such as LogiCoA™ power supply solutions. Features include a built-in 3ch analog comparator that can be linked to a timer and D/A converter that enables digital control of various parameters to support different power supply topologies.

■ LogiCoA™ MCU Specifications (Tentative)

Availability: Now (LogiCoA™ MCU samples)

TerminologyFully Digital Control Power Supply

A power supply controlled using digital technology. High-speed CPUs and DSPs can be used to precisely monitor and control various parameters such as voltage and current, improving power supply efficiency and reliability. What’s more, functions that are difficult to perform with analog control can be achieved, such as acquiring operation log data. However, CPUs and DSPs are expensive and consume a large amount of power, which can be a bottleneck in terms of costs and energy efficiency.

Analog Control Power Supply

A power supply configuration consisting of analog components. This type has become mainstream for power supplies 1kW and below due to its simplicity and low power consumption. On the other hand, implementing advanced functionality such as setting arbitrary parameters and logging data is difficult, requiring fully digital control that entails high costs and power consumption.

CPU (Central Processing Unit)

Responsible for executing programs and processing data. Handles calculations and processing as well as carrying out instructions according to a program.

DSP

A device that digitizes analog signals and performs operations such as analysis, filtering, and amplification on the converted digital signals. Flexible enough for high-speed processing and various applications, it plays an important role in circuits that handle digital signals, such as audio and image processing in addition to power supplies.

Online messageinquiry

Industry’s Highest* Rated Power! ROHM Unveils the UCR10C Series of Sintered Metal Shunt Resistors

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments |

| model | brand | To snap up |

|---|---|---|

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: