- Ameya360 Component Supply Platform >

- Trade news >

- Murata:What Are the Conditions for Increasing the Efficiency of Power Conversion and Motor Drives and for Expanding the Use of SiC and GaN Power Semiconductors?

Murata:What Are the Conditions for Increasing the Efficiency of Power Conversion and Motor Drives and for Expanding the Use of SiC and GaN Power Semiconductors?

Governments around the world and companies in all industries and businesses are coming together to engage in efforts to achieve carbon neutrality (Fig. 1). Every conceivable multifaceted decarbonization measure is being taken. This includes, for instance, the utilization of renewable energies such as solar power, the electrification of equipment that was previously used by burning fossil fuels, and the reduction in power consumption of existing devices like home appliances, IT equipment, and industrial motors.

Various countries and regions have introduced carbon pricing mechanisms as systems to shift greenhouse gas emissions from business activities to costs. As a result, in addition to being meaningful as social contribution, carbonization initiatives now have a clear numerical impact on the financial statements that serve as a report card for corporate management.

Full Model Change in Semiconductor Materials for the First Time in 50 Years

There has been an increase in activity for decarbonization efforts. Against this background, there is a field in semiconductors where the pace of the movement in technological innovation is rapidly accelerating. This is the power semiconductor field.

Power semiconductors are semiconductor devices that play the role of managing, controlling, and converting the power necessary to operate electrical and electronic equipment. These devices are built into so-called power electronics circuits. These circuits include power circuits that stably supply drive power to home appliances and IT equipment, power conversion circuits to transmit and distribute power without waste, and circuits that drive motors with high efficiency at a torque and rotational speed that can be controlled freely. These power semiconductors, which are key devices to realize a sustainable society, have now started to undergo a once-in-50-years full model change.

Power semiconductors have various device structures including MOSFET*1, IGBT*2, and diodes. They are used differently according to the purpose. Nevertheless, although the structure differs, silicon (Si) has consistently been used for more than 50 years as the device material. That is because Si has good electrical characteristics and has the property of being easy to process into various device structures at the same time.

*1: A Metal Oxide Semiconductor Field Effect Transistor (MOSFET) is a type of Field Effect Transistor. It functions as an electrical switch. These transistors consist of three layers: a metal, oxide, and semiconductor. The current is turned on and off by applying a voltage to the electrode called a gate.

*2: An Insulated Gate Bipolar Transistor (IGBT) is a transistor with a structure that combines a MOSFET and bipolar transistor. It is characterized by combining the high-speed operation of the MOSFET with the high withstand voltage and low resistance of the bipolar transistor.

However, Si-based power semiconductors are no longer able to clear the high level of technical requirements to further reduce the power consumption of various electrical and electronic equipment. To overcome this situation, progress is underway on the utilization of new materials such as silicon carbide (SiC) and gallium nitride (GaN), which are more suitable than Si as materials for power semiconductors. SiC and GaN have multiple physical properties and characteristics suitable for power semiconductors. These include their dielectric breakdown field strength (affects the withstand voltage), mobility (affects the operating speed), and thermal conductivity (affects reliability). If we can develop a device that brings out those excellent characteristics, we can realize power semiconductors with even higher performance.

SiC-based MOSFETs and diodes have already been commercialized. They are being used in electric vehicle (EV) motor drive inverters, DC/AC converters in solar power generation power conditioners, and other equipment. GaN-based HEMT*3 have also already been commercialized. They are now being used in AC converters for ultra-small PCs, chargers for smartphones, and other equipment.

*3: A High Electron Mobility Transistor (HEMT) is a Field Effect Transistor that enables high-speed switching by joining semiconductors with differing properties to induce electrons with high mobility.

Evolution of Capacitors, Inductors, and Other Equipment Is Essential to Draw out the Potential of SiC and GaN

It is not possible to draw out the full outstanding potential of power semiconductors made based on new materials simply by replacing the Si-based devices in existing power electronics circuits. This is because the other semiconductor ICs, passive components, and even the control software that comprise power electronics circuits have been developed and selected on the assumption they would be used in Si-based power semiconductors. It is necessary to newly re-develop and re-select these peripheral components as well to effectively utilize new material-based power semiconductors.

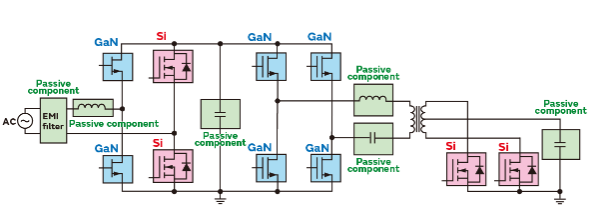

Fig. 2: Example of an AC/DC converter circuit utilizing a GaN-based power semiconductor used in data center servers and other technologies

For example, numerous GaN HEMTs are being used in AC/DC converter circuits that have adopted GaN HEMTs recently introduced to lower power consumption in the power supplies of data center servers (Fig. 2). It is possible to improve the switching frequency (operating frequency) of power electronics circuits by utilizing the features of GaN HEMTs in that they enable high-speed switching at high voltages. The reactance value of capacitors embedded into circuits and inductors in reactor signal processing circuits can be lower in circuits with a high operating frequency. In general, low reactance components have a small size. Therefore, it is possible to downsize the circuit board and to improve the power density. Similarly, introducing SiC MOSFETs even in inverter circuits which drive EV motors and other components enables the downsizing of peripheral components and also allows the overall inverter circuits to be made smaller and more lightweight.

On the other hand, a high level of noise may arise from high-voltage and high-speed switching power supplies. There is a possibility that noise may then adversely affect the operation of the peripheral equipment. Power supplies comprising power semiconductors made with SiC and GaN switch at an even higher frequency. Therefore, the risk of noise occurring further increases. Accordingly, stricter noise suppression is required than when using existing power electronics circuits. At that time, there is a need to use noise suppression components designed to be applied to high-voltage, large-current, and high-frequency circuits rather than those for conventional circuits.

In addition, there is also a need for small transformers that operate at even higher frequencies for transformers that are particularly heavy components even among passive components. Low profile planar transformers and other components have already been developed and launched onto the market under the assumption that they will be used in SiC- and GaN-based power semiconductors.

Attention Focusing on the Evolution of Peripheral Components in Addition to Power Semiconductors

Various types of semiconductors, not limited to power semiconductors, have been made based on Si up to now. Therefore, many existing electronic components have been developed under the implicit assumption that they will be used by being combined with Si-based semiconductors. It may become necessary to develop new products to suit the new technical requirements instead of simply searching for even better products among existing components to maximize the effect of introducing power semiconductors made with new materials.

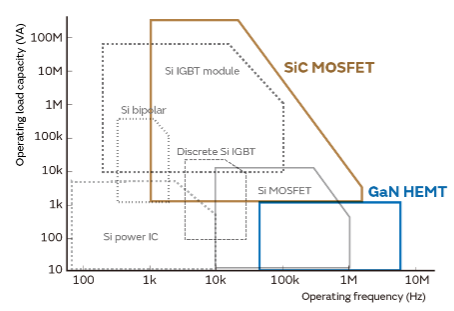

In general, Si-based power semiconductors tend to operate at lower speeds the greater the voltage and current they can handle (Fig. 3). That is the reason why there are not enough small capacitors and reactors that can handle high voltages and large currents. Moreover, there is a trend to simplify the heat dissipation system and to reduce the size, weight, and cost for SiC-based power semiconductors that can operate stably under high temperatures. In these cases, the passive components also need to have a guaranteed high reliability under a high-temperature environment.

The introduction of new materials in the power semiconductor field is a major move to update the electrical and electronic ecosystem that has been optimized to Si materials for more than 50 years. Therefore, we also want to pay a great deal of attention to the evolution of peripheral electronic components optimized for new materials.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: