- Ameya360 Component Supply Platform >

- Trade news >

- Fukui Murata Manufacturing to Establish New Ceramic Capacitor R&D Center Near Echizen-Takefu Station, Fukui Prefecture, in April 2026

Fukui Murata Manufacturing to Establish New Ceramic Capacitor R&D Center Near Echizen-Takefu Station, Fukui Prefecture, in April 2026

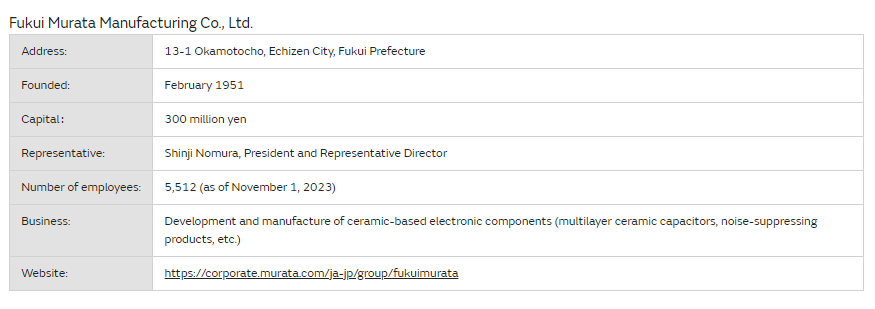

Fukui Murata Manufacturing Co., Ltd. (Echizen City, Fukui Prefecture), a manufacturing subsidiary of Murata Manufacturing Co., Ltd., will establish a new research and development base “Ceramic Capacitor R&D Center” near Echizen-Takefu Station in Fukui Prefecture. Construction will commence in November 2023 with the inauguration planned for April 2026.

The establishment of the Ceramic Capacitor R&D Center aims to improve the technological capabilities in the development and manufacture of ceramic capacitors, Murata Manufacturing’s core business. By creating a cutting-edge environment dedicated to research and development, Murata aims to facilitate higher-level R&D activities and nurture engineers. The center will also collaborate with other company sites and partner companies, with the aim of strengthening Murata’s capabilities in monozukuri (manufacturing) across the entire production process from product development to mass production.

Going forward, Murata will continue to drive advancements in its technological capabilities in order to provide innovative products and technologies to society and contribute to further growth in the electronics market.

Overview

■ Overview of facility

Site area: 55,075㎡

Floor area: 42,071㎡

Size: Steel framework construction; five stories above ground

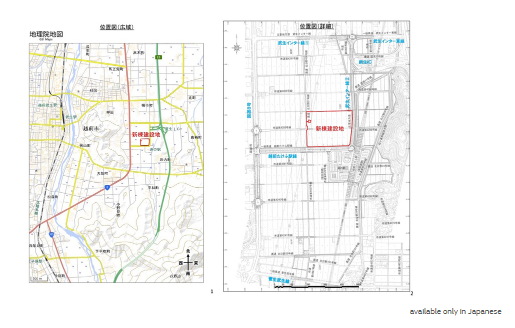

■Construction location: Oyacho, Echizen City, Fukui Prefecture

available only in Japanese

■Construction period: Groundbreaking November 2023; completion January 2026 (planned)

■Total investment: Approx. 35 billion yen (land and building costs)

■Number of employees: Approx. 800 (future projection)

■Site concepts

1. Enhancing development capabilities

With floors dedicated to R&D and an environment where new production processes and products can be created, and by collaborating with the geographically close Yasu Materials & Technology Development Division, the center will accelerate development of new products and new production processes. The center will also aim to create innovation by providing an environment where people with different values and ideas can gather and communicate easily.

2. Developing engineers

The center will aim to improve Murata’s monozukuri capabilities for ceramic capacitors by providing an environment where new hires, young employees, and engineers from affiliated companies can learn manufacturing basics and delve deeper into mechanisms.

3. Coexistence with the local community

In addition to greening around the building exterior, the center will promote the creation of spaces that blend with the surroundings. The company is also considering facility tours, internships, and accepting evacuees in times of disaster or when people are unable to return home, and will aim to make the site rooted in the community.

4. Environmental considerations

Within the premises, the company has plans to develop a green space open to local residents. The center will also have highly insulated exterior walls and window frames, air-conditioning and lighting controls linked to equipment and human activity, solar power generation facilities, and various other energy-saving and renewable energy technologies to aim for the achievement of ZEB Oriented*.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments |

| model | brand | To snap up |

|---|---|---|

| STM32F429IGT6 | STMicroelectronics | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: